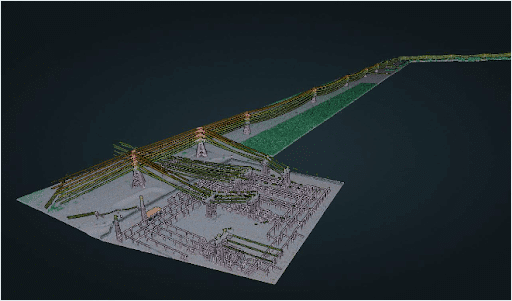

RANGER-XL

Point Density: 115 points per m^2

Height: 330 m AGL (approx.)

Speed: 50 m/s

Data Acquisition Time: 13 minutes

Point Density: 168 points per m^2

Height: 320m AGL

Speed: 55 knots

Data Acquisition Time: 26 minutes

Discover the comprehensive guide to selecting the right LiDAR system with our detailed LiDAR Selection Guide. This article covers everything from the basics of LiDAR technology to in-depth comparisons of current scanners. Learn about the technical specifications, platform configurations, and software considerations essential for optimizing your LiDAR mapping projects.

Whether you are in forestry, construction, or surveying, our guide provides the insights needed to choose the best LiDAR solution for your needs. Read on to understand the advantages of UAV LiDAR, the components that make up a LiDAR system, and how to achieve high precision and accuracy in your mapping endeavors.

Phoenix LiDAR System offers survey-grade LiDAR systems for a variety of industries and applications.

Join Phoenix LiDAR Systems and SkySkopes for a quick fly through video focused on the RANGER series of helicopter based mapping solutions. SkySkopes is a top-tier data service provider that operates a wide variety of advanced sensors and aircraft for transmission and distribution line inspections, oil and gas applications, and many other innovative use cases that focus on adding value.

Join the Phoenix LiDAR Systems September 2021 webinar, hosted by Conrad Conterno and Ben Adler, focusing on airborne LiDAR data acquisition with manned aircraft. This session highlights the advantages of using fixed-wing aircraft and helicopters for LiDAR mapping, including increased flight speed, height, and the ability to cover large areas efficiently. Conrad Conterno, the post-processing manager, and Ben Adler, CTO and co-founder, introduce the new mission guidance feature of SpatialExplorer, a software that enhances real-time flight mission execution.

Learn about the different mission types available in the flight planner, such as wide-area mapping, corridor mapping, and line points mode. Discover how to incorporate various sensor types and models for accurate planning, ensuring optimal density, overlap, and resolution. The webinar includes a detailed demonstration of MissionGuidance, showcasing tools like dynamic whiskers for real-time navigation and the touch-and-go mode for pilot-initiated flight lines.

Understand the importance of precise flight planning and execution for high-quality LiDAR data and efficient post-processing. The session concludes with a Q&A, addressing flight plan creation, altitude calculations, and system adaptability. Explore the future of LiDAR mapping with Phoenix LiDAR Systems’ advanced technology and mission guidance capabilities.

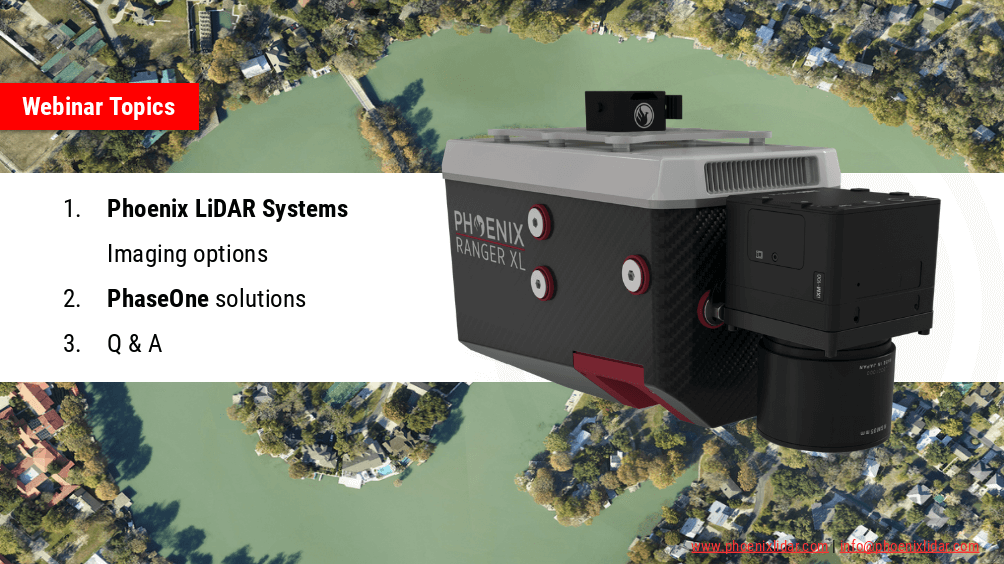

Join the Phoenix LiDAR Systems webinar on advanced imaging systems, held on April 21, 2021. Hosted by Conrad Conterno, Head of Post-Processing, and Justin Wyatt, VP of Sales at Phoenix LiDAR Systems, along with Nick Nelio, Inspection Sales Manager for Phase One, this session dives into how Phoenix LiDAR’s data collection tools integrate with Phase One’s cutting-edge imaging systems to enhance remote sensing capabilities.

Conrad Conterno opens with an overview of Phoenix LiDAR’s custom mapping solutions, emphasizing LiDAR sensor integration for superior data acquisition and analysis. He introduces various advanced camera options, including the lightweight custom A6K Light for UAV-based mapping, dual oblique cameras for enhanced colorization, multispectral solutions for detailed vegetation analysis, thermal mapping cameras for environmental monitoring, and hyperspectral sensors for precise spectral analysis.

Nick Nelio then showcases Phase One’s high-resolution, medium-format cameras, focusing on the 4-band solution that combines RGB and near-infrared imagery, ideal for crop analysis and environmental monitoring. He also presents the Phase One P3 payload for inspection applications and the IX Mach 5 controller designed for efficient geospatial missions.

Throughout the webinar, the benefits of direct geo-referencing and the seamless integration of multiple sensors into single payloads are highlighted. The hosts address audience questions on the accuracy of dual-camera systems, post-processing challenges, and the applications of hyperspectral imaging.

The session concludes with Justin Wyatt and Nick Nelio emphasizing their collaborative approach to delivering tailored solutions and inviting viewers to contact them for personalized consultations.

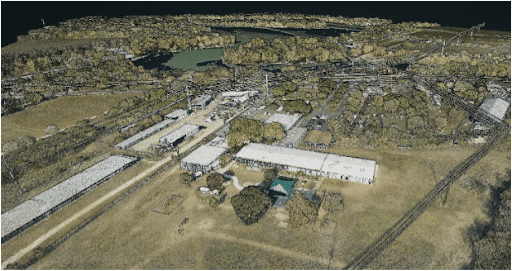

A few weeks ago we posted a video of a completed Ranger-XL ready for shipment. Here’s a peek at a recent dataset collected by that same Ranger-XL coupled with the 100MP Phase One 4-band Solution. This urban corridor was easily captured with a single pass, creating a stunning dataset with high Imagery and LiDAR resolution. Data specs: 80 Points Per Square Meter Average for LiDAR and 3cm GSD for imagery.